SPONSORED CONTENT - Over the last few years, the textile industry has seen a lot of traction on the topic of Sustainability. One of the discussions is on Cleaner Production (CP) as the supply chain struggles to meet the demanding needs of consumers and addressing environmental impacts versus business performance. Today, the supply chain needs to respond promptly with effective solutions for the challenging business landscape such as to optimize resource consumption and develop products that conserve resources.

In a recent industry report by The Pulse of the Fashion Report[1], it highlighted the fashion industry has slowed down social and environmental improvements compared to previous years by one-third. The findings were also supported by CEOs interviewed during an Accenture study[2], whereby they acknowledged that their industries and businesses are not doing enough to meet the Sustainable Development Goals[3]. Ironically, the industry does not short of opportunities to reduce environmental impacts and more can be done. Large amounts of water and energy are used in textile dyeing and finishing, and the total amount of chemical used in a textile varies between 10% and 100% by weight of the produced textile product[4]. The industry needs to take a proactive and yet coordinated approach so that the entire industry transformation process of the product life cycle achieves maximum effectiveness.

Cleaner Production approaches

Sustainable Textile Solutions (STS), a UK based consultancy, believes that Cleaner Production is the first step towards industry transformation. Cleaner Production, as defined by the United Nations Environmental Program, is the continuous application of an integrated preventive environmental strategy applied to processes, products, and services to increase overall efficiency and reduce risks to humans and the environment. “According to the Ellen McArthur Foundation, total clothing sales have a potential of reaching 175 million tonnes in 2050. By delaying Cleaner Production any further, we will face the risk of textiles production using more than 25% of the carbon budget for a 2°C pathway, microfibre release into oceans will grow to 0.7 tonnes per year, with more than 150 million tonnes of clothing that needs be landfilled or burned in 2050,[5]” elaborated Tamara Wulf, Senior Project Officer at STS.

The good news is, Clean Production is highly desired by brands and retailers, as most European and American Brands and Retailers outlined sustainability strategies that included Energy and Emissions Reduction, Water Stewardship, Zero Discharge of Hazardous Chemicals and more Sustainable Material choices in their scope. “As a result, production units need to respond to the call to strengthen their value proposition when working with these brands and retailers,” emphasized Tamara.

Getting Started

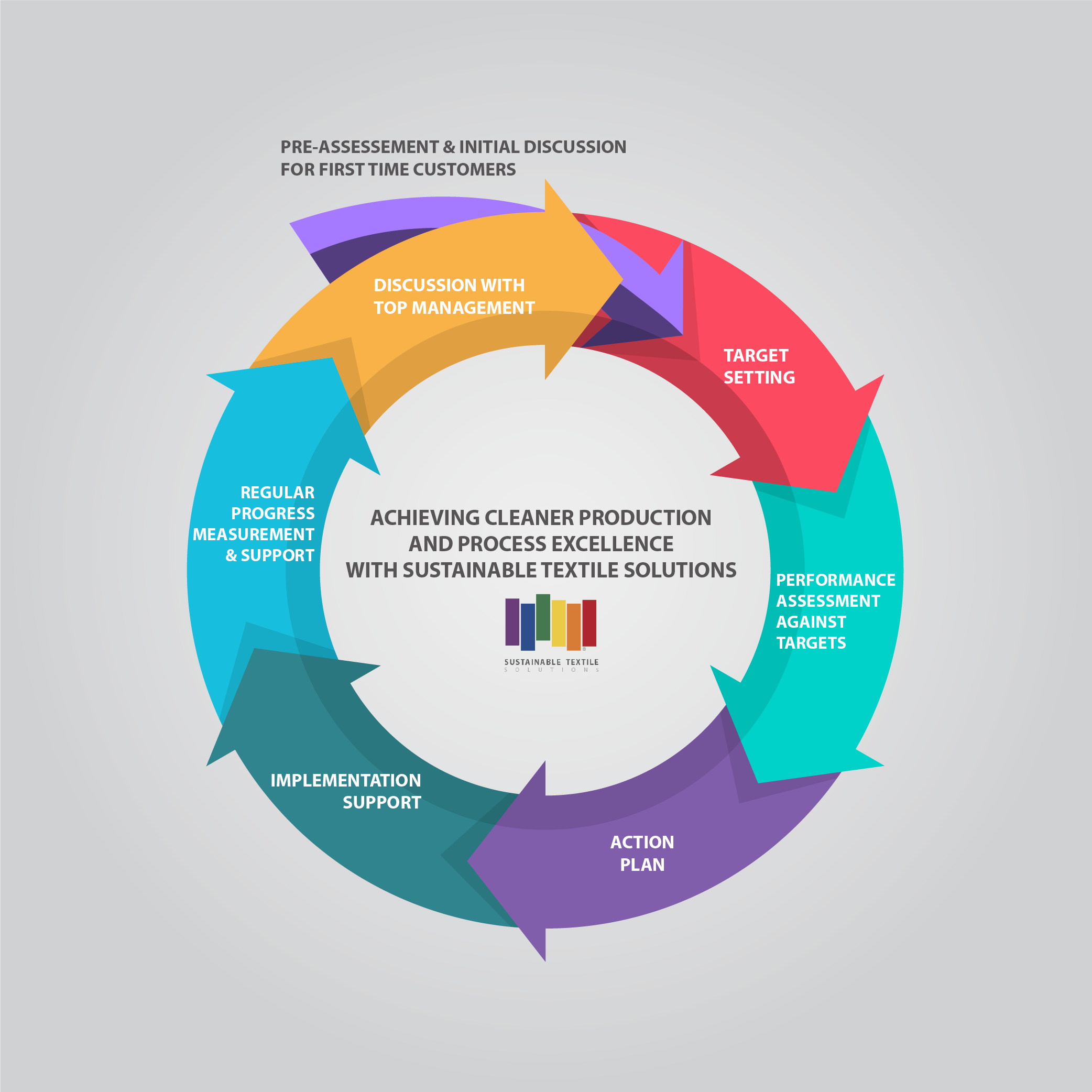

Sustainable Textile Solutions (STS) has integrated Process Excellence into their Clean Production Services and will scale up the program in 2020. During the pre-assessment stage, the expert team identifies opportunities for improvements and carves out the benefits: Cost savings and quality improvements, reducing inefficiencies and resources, and compliance with environmental laws, gives production units a competitive edge of meeting customer sustainability requirements such as that of Zero Discharge of Hazardous Chemicals [6]. The overall objective is to help the factories recognize the benefits of Cleaner Production alongside with a fully functional wastewater treatment plan through making them relevant to production realities. Current challenges are discussed with Top Management and achievable targets are set, based on data such as water and energy consumption and the chemical inventory list.

Assessment and Implementation

With facts and figures on hand, the expert from STS will carry out a detailed analysis of the production based on current performance in the areas of process excellence, water, energy, waste, wastewater, emissions, and chemicals to identify opportunities for First Time Right, reduction of Turnaround and Processing Time or Waste Reduction. Gaps against the targets set and improvement actions will be tabled for discussions to facilitate the actual implementation process as needed. Examples include how to optimize the production flow to save time, review of dyeing recipes to reduce chemical consumption or substitute hazardous chemicals, improve Wastewater Treatment Plant performance to avoid any harmful effects are caused by the effluent and reduce the expenditure on water acquisition by evaluating opportunities for water recycling.

An effective program coordinated by experts from Sustainable Textile Solutions by BluWin will bring fore better economic, environmental, and societal outcomes by adopting the industry best practices.

Since 2012, Sustainable Textile Solutions has been providing diverse solutions to brands, retailers and industry partners, implementing sustainable textile and leather production that meets quality and sustainability requirements. Speak with This email address is being protected from spambots. You need JavaScript enabled to view it. today.

[1]https://globalfashionagenda.com/pulse-2019-update/#

[2]https://www.accenture.com/_acnmedia/PDF-109/Accenture-UNGC-CEO-Study.pdf#zoom=50

[3]https://www.un.org/sustainabledevelopment/sustainable-development-goals/

[4]https://publications.jrc.ec.europa.eu/repository/bitstream/JRC85895/impro%20textiles_final%20report%20edited_pubsy%20web.pdf

[5]https://www.ellenmacarthurfoundation.org/assets/downloads/A-New-Textiles-Economy_Full-Report_Updated_1-12-17.pdf

[6]https://www.roadmaptozero.com/process