SPONSORED CONTENT - The LYCRA Company and Qore® join forces to create next generation bio-derived LYCRA® fibre with QIRA®

There’s a transformative, more sustainable spandex on the horizon. And it’s the result of an exciting collaboration between leading fibre and feedstock providers. The LYCRA Company - known for its innovative fibre and fabric solutions - has teamed up with Qore® - a joint venture of Cargill and HELM - to enable the world’s first large-scale commercial production of bio-derived spandex. LYCRA® fibre - which is used across many garment types from leggings to intimates, to jeans and diapers - will soon integrate renewable bio-derived QIRA® from Qore®.

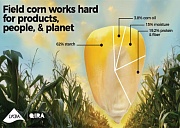

The main ingredient in LYCRA® fiber is PTMEG which is derived from BDO (1,4-butanediol). Today this is produced from fossil-based resources. QIRA® is the next generation BDO - made from annually renewable field corn instead of finite, fossil-based materials.

The Qore facility at Cargill’s biotechnology campus and corn refining operation in Eddyville, Iowa, USA, will source field corn within a 100-mile radius of its location from farms that are mostly run on wind power and require little to no irrigation, which will help reduce greenhouse-gas emissions and water usage and provides local farmers with a reliable market for their crops.

From Farm to Fibre

Once QIRA® is converted into PTMEG, it is used to comprise 70% of the total LYCRA® fibre content. The bio-derived PTMEG is mixed with other ingredients and additives and then spun into fibre. The result is LYCRA® fibre made with 70% renewable content. According to a 2022 Screening Life Cycle Assessment (LCA), the potential reduction in the carbon footprint of renewable LYCRA® fibre is up to 44%* versus original LYCRA® fibre.

Creating Positive Impact

According to the World Economic Forum, the fashion industry and its supply chain are responsible for 10% of worldwide GHG (greenhouse gas) emissions annually. This signifies both a tremendous responsibility and opportunity for manufacturers and brands to innovate and collaborate to find transformative solutions.

So, how can a leading supplier of spandex create significant positive environmental impact? Julien Born, CEO of The LYCRA Company, explains, “Since the largest impact category for our fibre is raw materials, we knew we had to focus on our ingredients to help reduce our footprint and meet our sustainability goals. By adopting QIRA®, we’re making a significant commitment that will also enable our customers to reduce their own product footprints.”

Just as important as its sustainability benefits, bio-derived LYCRA® fibre made with QIRA® meets the same high-quality performance parameters of traditional LYCRA® fibre. This is a key benefit for brands and retailers as processes will not need to be redesigned, and fabrics will continue to have the same excellent performance of stretch, strength, and durability as from traditional LYCRA® fibre.

The collaboration between The LYCRA Company and Qore® demonstrates how companies across industries can and should work together to address climate change. Jon Veldhouse, CEO of Qore®, comments, “Developing sustainable solutions is no doubt a collective effort and our collaboration of LYCRA® fibre with QIRA® is bringing an innovative, sustainable solution, at scale to brands and retailers.”

Production of renewable LYCRA® fibre made with QIRA® is expected to begin in the second half of 2024 with commercial product available at scale in late 2024.

To learn more, visit LYCRA.com/QIRA.

*Estimate from Cradle-to-Gate Screening LCA for a representative LYCRA® fibre manufacturing facility, June 2022, prepared by Ramboll US Consulting, Inc.